Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Cable railing it’s chosen for its minimalist aesthetic and cost-effectiveness in both residential and commercial settings.

Key components of a cable railing system include posts, handrails, termination posts (end or corner posts), intermediate posts (supporting cables), and a top rail necessary for safety compliance.

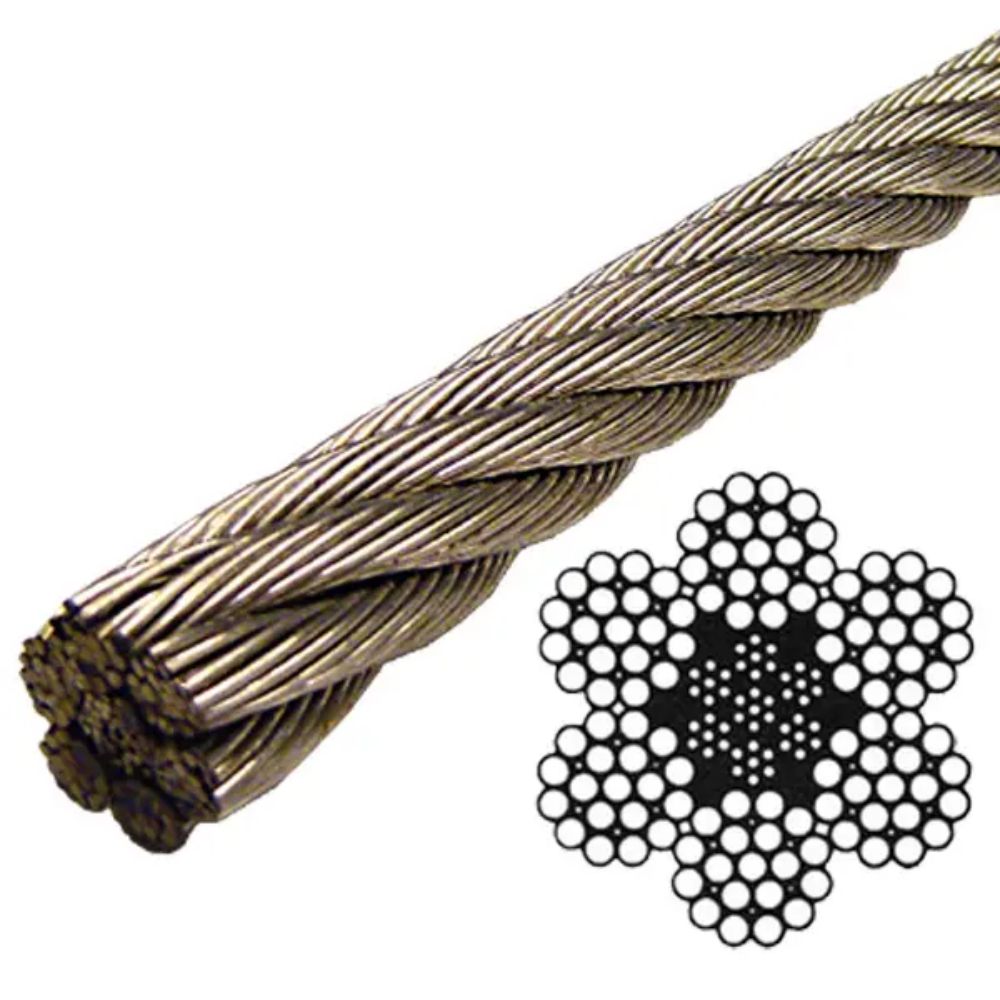

Cable diameters typically range between 1/8” (minimalist residential look) and 3/16” (more substantial, industrial appeal). The industry standard cable construction is 1×19, known for its clean cut and low-stretch properties.

Components like end stops secure cables at termination posts, while tensioners tighten cables for stability. Post protectors are optional but recommended to enhance appearance and prevent cable abrasion, especially in intermediate pass-thru posts.

Assembly involves swaging (crimping) tensioning and end stop components to cables using a swager tool, ensuring secure attachment.

A cable railing system is segmented into “cable runs,” each consisting of tensioned cables secured by end stops and tensioners. Runs are divided by factors like corners or obstructions, ensuring structural integrity and aesthetic continuity.

Types of cable runs include straight runs (perpendicular to posts), angled runs (consistent angle, often on stairs), and transitional runs (changing angles at intermediate posts). Identifying these runs is crucial for planning a customized cable railing system.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: