Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Regular inspections are crucial for:

Ensure all parts of the sling are visible. Lay the sling out so every piece is accessible.

Remove dirt and debris with wire brushes and rags to facilitate a clear visual inspection.

Immediately dispose of any rope deemed unsuitable for use to avoid safety risks.

Wire ropes are vital in various applications, and their proper care and inspection are essential for safety and longevity. Following these guidelines can help reduce the risk of accidents, extend the service life of wire ropes, and ensure compliance with industry standards.

For more information on wire rope safety and lifting, contact us today! Our experts are ready to provide the guidance and support you need.

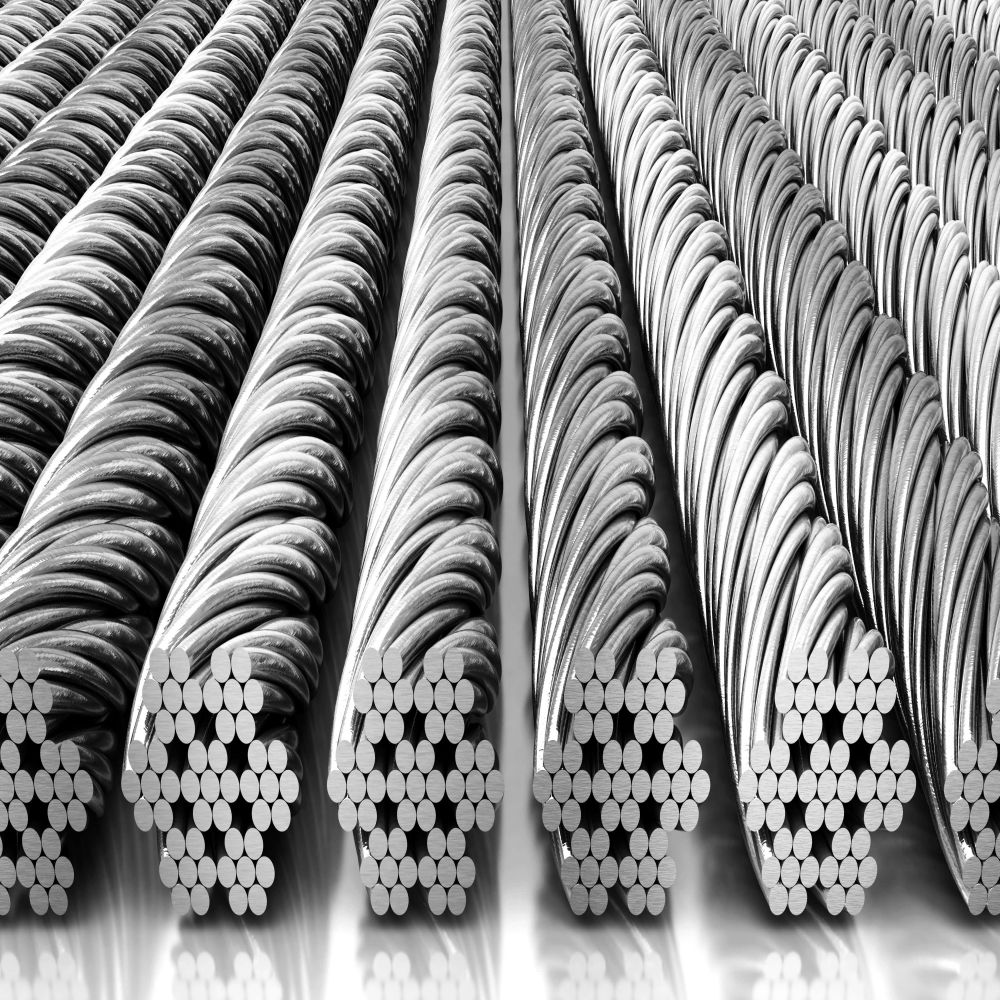

A: We offer 302, 304, 316 stainless steel in diameters from 0.15mm to 50mm.

We have various cable constructions and finishes (bright, dull). Black/white PVC coating available.

A: Contact our team to discuss your requirements.

Pricing & Shipping:

A: We source high-quality materials competitively.

A: FOB, CFR, CIF, door-to-door. We’ll advise on the most economical option.

A: We offer stock and efficient mill deliveries with minimized lead times. We’ll provide an estimated timeframe upon confirming your order.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Abrasion resistance is necessary if the wire rope will be dragged over rough surfaces. Ropes made of many small wires are not ideal for resisting abrasion as they wear down faster. Instead, opt for ropes with fewer and larger wires to handle abrasive conditions better.