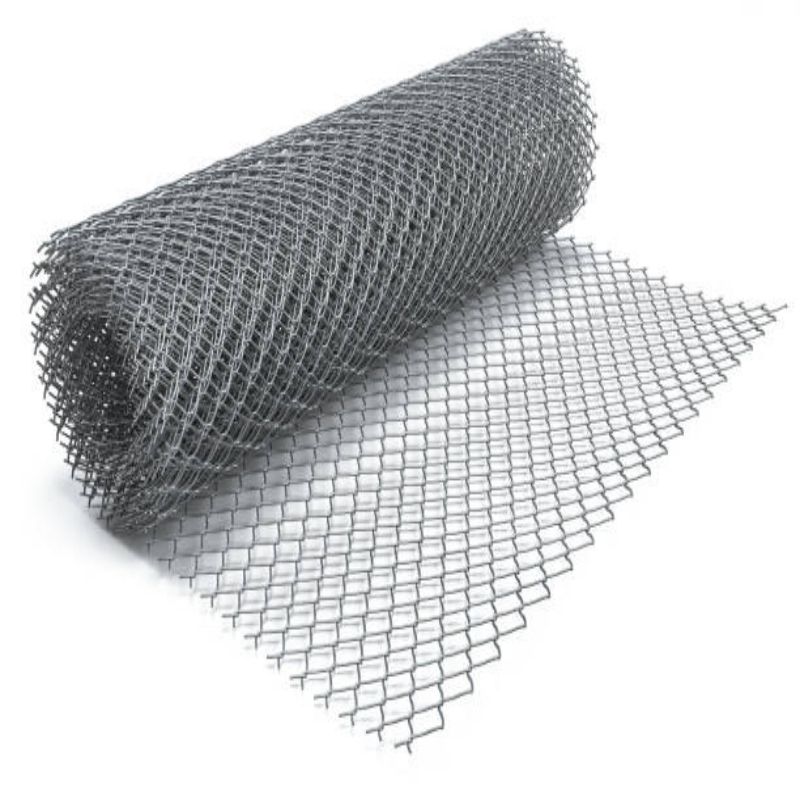

Wire Drawing

The process begins with wire drawing, where large steel rods are pulled through a series of dies to reduce their diameter. This process is repeated multiple times to achieve the desired thickness. The resulting wires are strong and have uniform diameters, essential for the integrity of the final product.

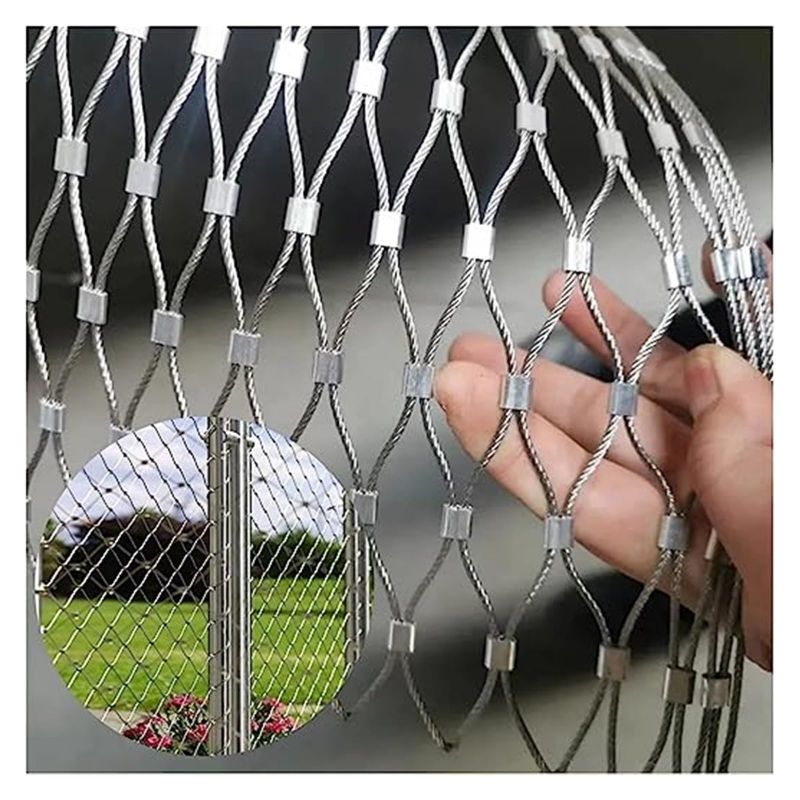

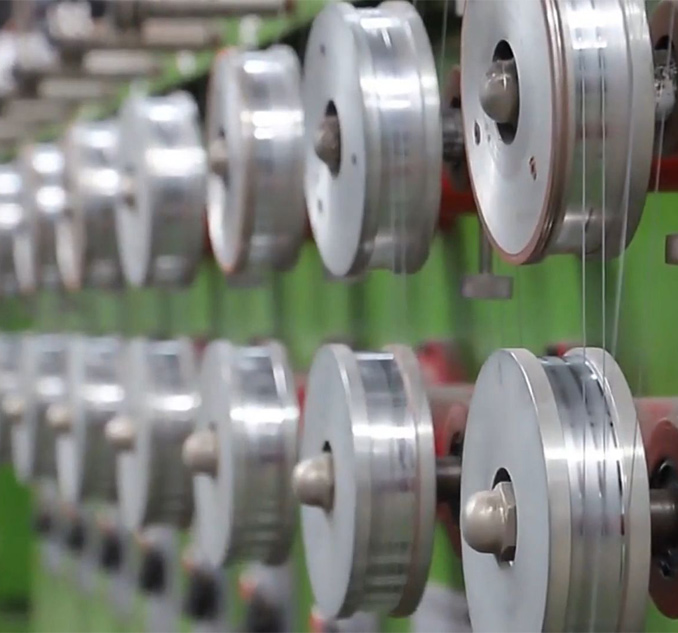

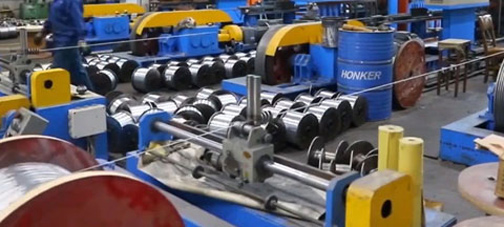

Stranding

In this step, individual wires are twisted together to form strands. The image shows multiple wires being fed into a stranding machine. Depending on the required construction, these strands can be made from various wire configurations (e.g., 1×7, 1×19, 6×7). The stranding machine ensures that the wires are twisted with precise tension and alignment.

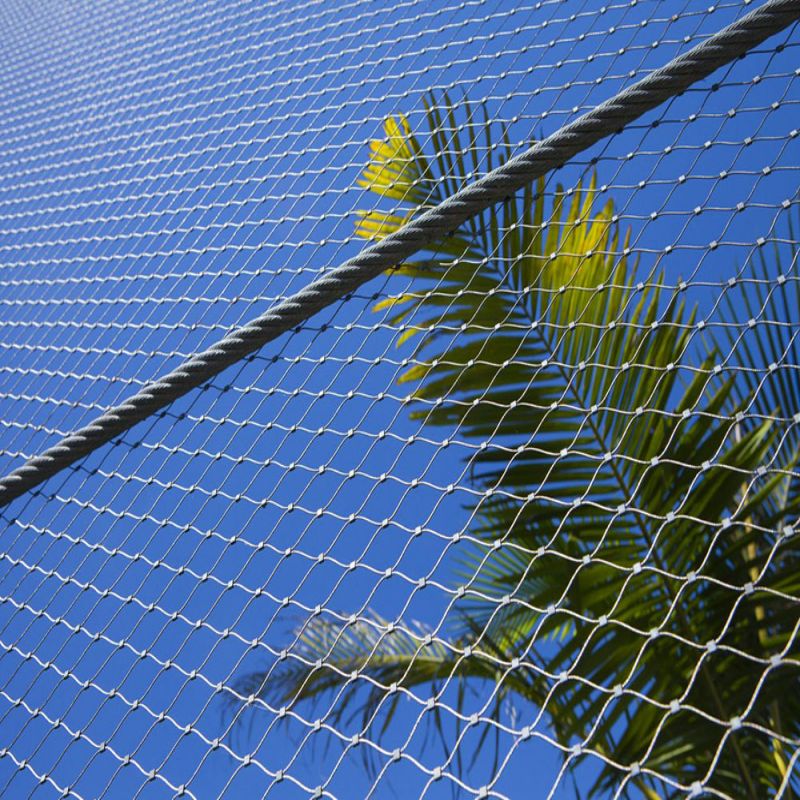

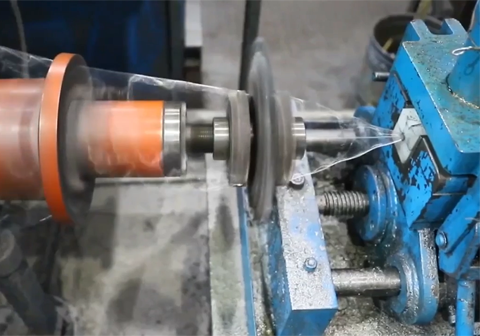

Strand Compaction

For some wire ropes, strands undergo a compaction process to increase density and reduce the diameter. This compaction enhances the rope’s strength and fatigue resistance, making it suitable for more demanding applications.