Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Wire ropes are indispensable tools across various industries, from construction to maritime applications, due to their strength and flexibility. However, two significant issues often plague their performance: over-torque and rotation. These problems can lead to inefficiencies, equipment damage, and even severe safety hazards. To mitigate these risks, the use of rotation-resistant wire ropes has emerged as a reliable and cost-effective solution. This comprehensive guide explores the intricacies of these specialized ropes, their design, usage, and the critical operational practices necessary to ensure safety and efficiency.

Wire ropes are subjected to various forces and stresses during their operation, with torque and rotation being among the most challenging to manage. Torque refers to the twisting force that can cause a wire rope to unwind or rotate under tension. This phenomenon can lead to the destabilization of the rope, resulting in equipment malfunction or failure, and pose serious safety hazards to personnel.

When a wire rope rotates or twists excessively, it can cause significant issues, including:

Excessive rotation can weaken the rope’s structure, leading to premature wear and tear.

Rotational forces can disrupt the alignment and operation of machinery and equipment.

Uncontrolled rotation increases the risk of accidents, potentially leading to severe injuries or fatalities.

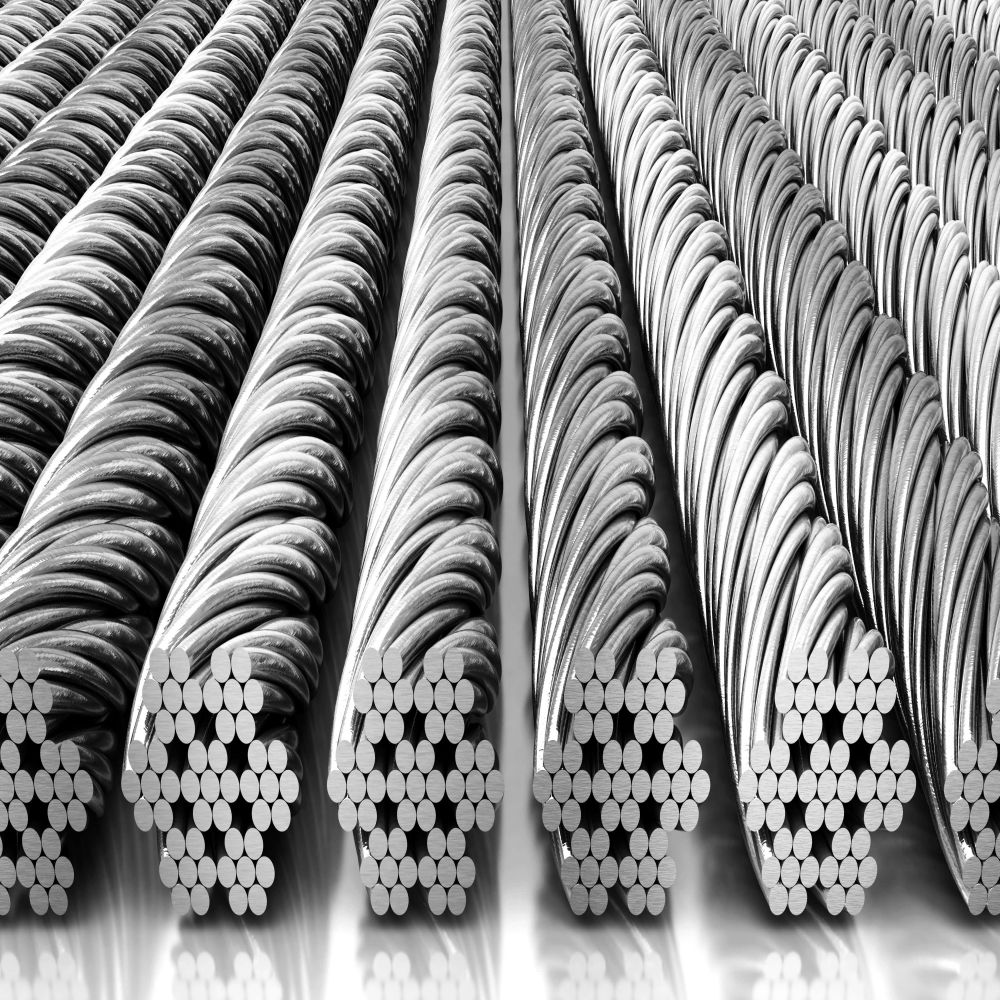

Rotation-resistant wire ropes are specifically engineered to address the challenges of over-torque and rotation. These ropes are designed with a contra-helically laid construction, which means the outer strands are laid in the opposite direction to the inner strands. This unique design counteracts the rotational forces that occur when the rope is under load, significantly reducing the torque experienced during normal working conditions.

Using rotation-resistant wire ropes offers several key benefits:

To maximize the benefits of rotation-resistant wire ropes, it is essential to implement best practices and preventive measures. Here are some guidelines for preventing operational issues and ensuring the safe use of these ropes:

Rotation-resistant wire ropes are a vital component in many industries, offering enhanced stability, safety, and longevity. By understanding their design, capabilities, and limitations, and by implementing best practices for their use, organizations can maximize their benefits and ensure the safety and efficiency of their operations. Whether in construction, maritime, aviation, or other industries, the proper use of rotation-resistant wire ropes is essential for achieving optimal performance and minimizing risks.

A: We offer 302, 304, 316 stainless steel

A: Contact our team to discuss your requirements.

A: We source high-quality materials competitively.

A: FOB, CFR, CIF, door-to-door. We’ll advise on the most economical option.

A: We offer stock and efficient mill deliveries with minimized lead times. We’ll provide an estimated timeframe upon confirming your order.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Abrasion resistance is necessary if the wire rope will be dragged over rough surfaces. Ropes made of many small wires are not ideal for resisting abrasion as they wear down faster. Instead, opt for ropes with fewer and larger wires to handle abrasive conditions better.