Related Products

Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

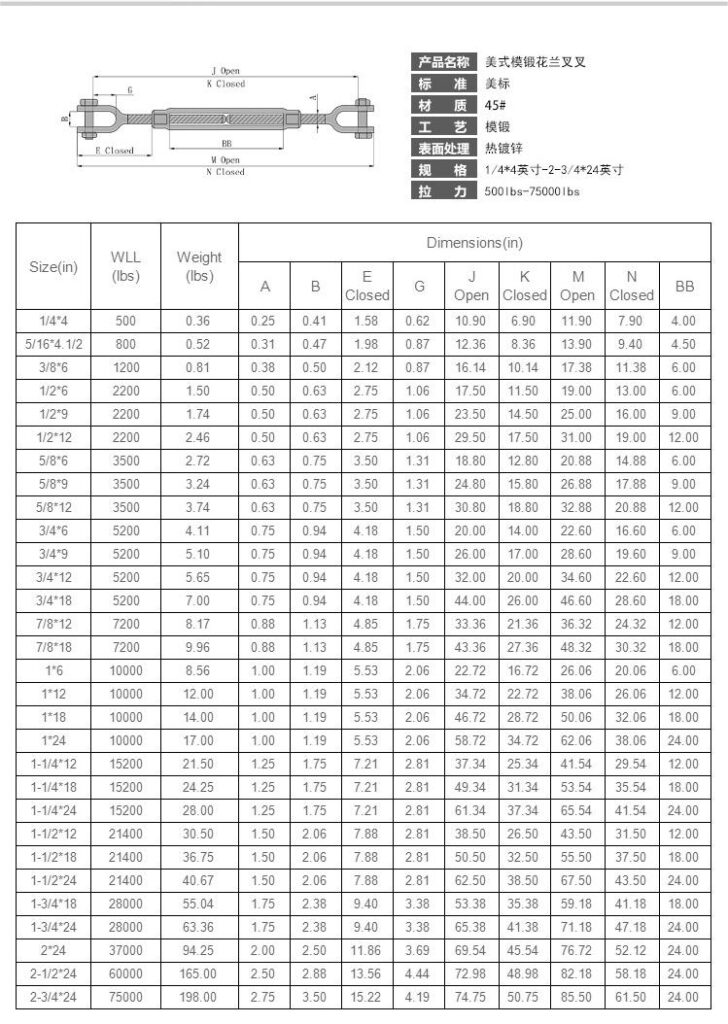

Turnbuckles are commonly used in construction, rigging, and maritime applications to secure loads and ensure stability. They are typically made from durable materials such as galvanized steel or stainless steel to withstand harsh environmental conditions.

Eye/Eye Turnbuckle: Features an eye at both ends for connecting to components with shackles or similar fittings.

Hook/Hook Turnbuckle: Has hooks on both ends, allowing for quick attachment and detachment from other components.

Jaw/Jaw Turnbuckle: Equipped with jaws and clevis pins at both ends for secure and stable connections, often used where rotation might be an issue.

Eye/Hook Turnbuckle: One end has an eye, and the other end has a hook, providing versatility in connections.

Jaw/Eye Turnbuckle: Combines a jaw on one end and an eye on the other, offering different attachment options.

Jaw/Hook Turnbuckle: Features a jaw on one end and a hook on the other, useful for varied connection requirements.

Turnbuckle with Toggle: Includes a toggle at one or both ends, providing additional flexibility and alignment capabilities.

Cost Efficiency: We procure top-quality materials at competitive rates, ensuring maximum value for your investment.

Global Shipping Expertise: Streamline your logistics with our comprehensive shipping solutions, including FOB, CFR, CIF, and door-to-door delivery options.

Quality Assurance: Transparency is our priority. Upon request, we furnish raw material test certificates and final dimensional statements to ensure your peace of mind.

Prompt Response: Our committed team guarantees a reply within 24 hours, often responding within the same hour of your inquiry.

Inventory Management and Timely Deliveries: We provide both readily available stock and efficient deliveries from mills, minimizing lead times.

Customer-Focused Approach: We build trust through honest solutions and realistic timelines.

Adjustable Tension: Turnbuckles allow for precise tension adjustments, which is essential for ensuring the stability and security of loads.

Versatility: Available in various types and sizes, turnbuckles can be used in a wide range of applications, including construction, rigging, and maritime operations.

Durability: Made from strong materials like galvanized or stainless steel, turnbuckles can withstand significant stress and harsh environmental conditions, ensuring long service life.

Corrosion Resistance: Materials like galvanized steel and stainless steel offer excellent resistance to corrosion, making turnbuckles suitable for outdoor and marine use.

Ease of Use: Turnbuckles are relatively easy to install and adjust, allowing for quick and efficient setup and modifications as needed.

Safety: By providing a reliable means of adjusting tension, turnbuckles help ensure the safety and stability of structures and loads, reducing the risk of failure.

Cost-Effective: Turnbuckles offer a cost-effective solution for tensioning and securing applications, combining affordability with high performance and reliabilit

Galvanized Steel: Steel that has been coated with a layer of zinc to prevent corrosion. Galvanized turnbuckles are strong and offer good protection against rust, making them suitable for outdoor and marine applications.

Stainless Steel: Known for its excellent corrosion resistance, stainless steel is ideal for environments exposed to moisture, chemicals, and saltwater. Stainless steel turnbuckles are highly durable and require minimal maintenance.

Carbon Steel: Used for applications where high strength is essential. Carbon steel turnbuckles are strong and durable but may require additional protective coatings to prevent corrosion.

Wire rope turnbuckles are widely used across various industries and applications due to their ability to precisely adjust tension and ensure secure connections. Here are some common uses:

Construction

Suspension Bridges: Turnbuckles are used to adjust the tension of cables in suspension bridges, ensuring stability and proper load distribution.

Scaffolding: Turnbuckles provide stability and support to scaffolding structures, allowing for precise adjustments to maintain balance and safety.

Marine and Maritime

Rigging: Used in sailboats and ships to adjust the tension of rigging lines, ensuring proper sail performance and stability.

Docking Lines: Turnbuckles are used to secure and adjust the tension of docking lines for ships and boats.

Aerospace

Aircraft Control Systems: Turnbuckles are employed in control cable systems to adjust the tension and ensure precise control of aircraft surfaces.

Satellite Systems: Used to maintain tension in structural components of satellites.

Industrial

Cranes and Hoists: Turnbuckles adjust the tension of cables in cranes and hoists, ensuring safe and efficient lifting operations.

Heavy Machinery: Used to secure and tension cables in various types of heavy machinery.

Telecommunications

Antenna Towers: Turnbuckles are used to tension guy wires that support antenna towers, ensuring stability and proper alignment.

Agriculture Fencing: Turnbuckles are used to tension wire fencing, ensuring it remains taut and secure.

Greenhouses: Used to secure and adjust the tension of support structures in greenhouses.

Entertainment and Events Stage Rigging: Turnbuckles are employed to secure and adjust the tension of cables used in stage rigging for lighting, scenery, and sound equipment.

Tent Structures: Used to tension and stabilize large tent structures for events.

Residential Deck Railings: Turnbuckles are used to tension cables in deck railings, providing a modern and secure railing solution.

Trellises and Pergolas: Employed to tension and secure cables in garden structures

A: A wire rope turnbuckle is a device used to adjust the tension or length of wire ropes and cables. It consists of two threaded eye bolts connected by a central body that can be rotated to alter the distance between the bolts.

A: Wire rope turnbuckles are commonly used in construction, rigging, maritime applications, and various other industries that require precise tension adjustments for securing loads and ensuring stability.

A: Wire rope turnbuckles are typically made from durable materials such as galvanized steel or stainless steel to withstand harsh environmental conditions and prevent corrosion.

A: To adjust a wire rope turnbuckle, you rotate the central body. This action either increases or decreases the distance between the two threaded eye bolts, thereby adjusting the tension or length of the wire rope or cable.

A: To adjust a wire rope turnbuckle, you rotate the central body. This action either increases or decreases the distance between the two threaded eye bolts, thereby adjusting the tension or length of the wire rope or cable.

A: Wire rope turnbuckles come in a variety of sizes to accommodate different load capacities and applications. The size you need depends on the specific requirements of your project..

A: Yes, there are several types of wire rope turnbuckles, including those with different end fittings such as eye/eye, hook/hook, jaw/jaw, and combinations thereof. Each type is designed for specific applications and attachment methods.

A: Yes, wire rope turnbuckles are often used in outdoor applications. For outdoor use, it is important to choose turnbuckles made from materials like galvanized st

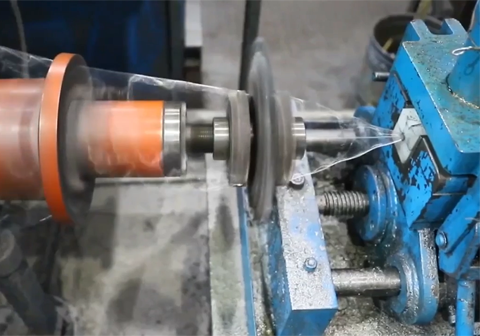

The process begins with wire drawing, where large steel rods are pulled through a series of dies to reduce their diameter. This process is repeated multiple times to achieve the desired thickness. The resulting wires are strong and have uniform diameters, essential for the integrity of the final product.

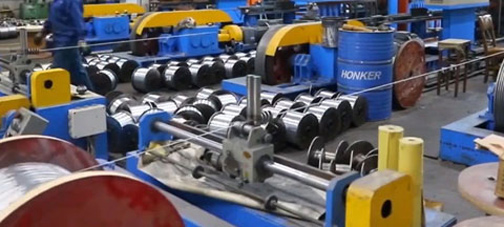

In this step, individual wires are twisted together to form strands. The image shows multiple wires being fed into a stranding machine. Depending on the required construction, these strands can be made from various wire configurations (e.g., 1×7, 1×19, 6×7). The stranding machine ensures that the wires are twisted with precise tension and alignment

For some wire ropes, strands undergo a compaction process to increase density and reduce the diameter. This compaction enhances the rope’s strength and fatigue resistance, making it suitable for more demanding applications.

The next step involves twisting the strands together to form the final wire rope. This is known as closing or laying. The image illustrates multiple spools feeding strands into a closing machine, where they are helically twisted to form a rope. Different constructions such as 6×19 or 7×7 are achieved by varying the number and arrangement of strands.

For additional protection, some wire ropes are coated with materials like PVC. The coating process involves passing the wire rope through a coating machine that applies a uniform layer of protective material. Black and white PVC coatings are common, providing extra resistance to environmental factors.

Throughout the production process, rigorous quality control measures are implemented. This includes visual inspections, dimensional checks, and mechanical testing (such as tensile strength tests). The image likely represents part of this quality control process, ensuring each wire rope meets the specified standards.

Founded in 1989, our company has established itself as a leading expert in sourcing, designing, and producing custom wire rope solutions for a broad spectrum of industries. We work closely with a diverse range of clients, including buyers, engineers, architects, designers, and project managers, to deliver exceptional results that consistently exceed expectations.

Our team is deeply passionate about wire rope and dedicated to building enduring relationships with our customers. We aim to be a trusted and integral part of their supply chain, going the extra mile to ensure the highest quality by adhering to the strictest industry standards. Our in-house testing and material analysis equipment enable us to thoroughly test and certify all wire rope, fittings, and assemblies we produce.

We serve a wide array of sectors, including marine, outdoor adventure, fall arrest, fitness, machinery, construction, defense, engineering, vehicle recovery, fencing, agriculture, shade sails, theater, lighting, pest control, shop fitting, and interior design. In addition to wire rope, we also provide the necessary tooling and machinery to meet your specific needs.

Our headquarters and production facility are located in Taian City, Shandong Province, China. With a global network of trusted partners, we are confident in our ability to offer exceptional lead times and meticulously managed delivery schedules, no matter your location or project requirements. We are driven by a vision to accelerate our growth beyond 2020, creating new and exciting opportunities for our dedicated and passionate team.

One of the most significant trends in the special steel wire rope industry is the development of high-performance materials. Traditional steel wire ropes have been made from carbon steel, which offers a balance of strength and affordability. However, the increasing demand for more robust and durable materials has led to the exploration of alternative alloys, such as stainless steel and galvanized steel. These materials offer enhanced corrosion resistance, increased strength, and improved fatigue life, making them ideal for use in harsh environments and demanding applications.

One of the most significant trends in the special steel wire rope industry is the development of high-performance materials. Traditional steel wire ropes have been made from carbon steel, which offers a balance of strength and affordability. However, the increasing lack Vinyl-Coated Stainless Steel Wire Rope demand for more robust and durable materials has led to the exploration of alternative alloys, such as stainless steel and galvanized steel. These materials offer enhanced corrosion resistance, increased strength, and improved fatigue life, making them ideal for use in harsh environments and demanding applications.