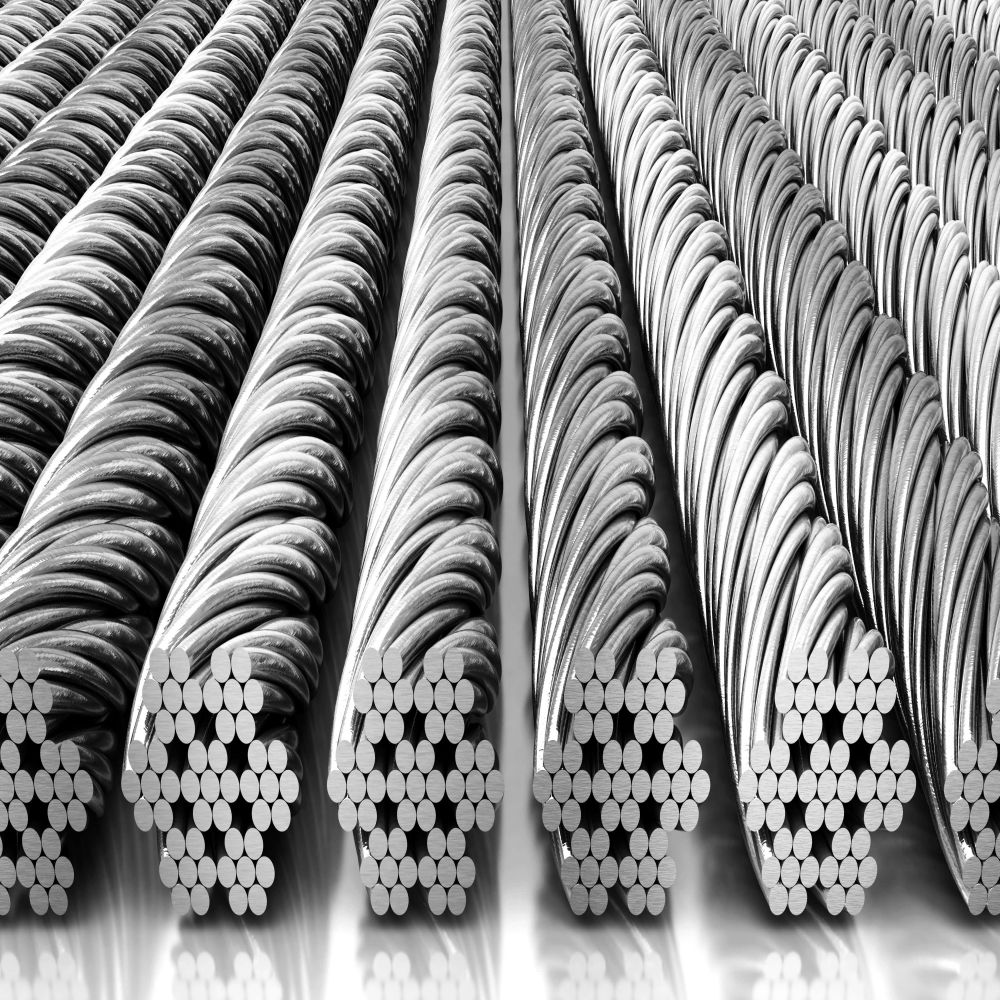

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Selecting the appropriate wire rope construction for your specific needs is critical. Using the wrong type can lead to several issues, including:

By understanding wire rope specifications and the differences between various constructions, individuals can ensure they select the right type for their applications. This not only optimizes performance and safety but also helps in managing costs effectively. Always ensure you are purchasing the correct rigging supplies to meet your specific needs, and avoid the pitfalls of selecting ropes for the wrong reasons.

For more detailed guidance on choosing the right wire rope construction for your needs, consult with a specialist or refer to industry standards and specifications.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: