Related Products

Stainless wire rope is a versatile and durable material widely used in various industries due to its strength, corrosion resistance, and flexibility.

Galvanized wire rope combines the strength of steel with the protective benefits of zinc coating, making it a durable and reliable choice for demanding applications across various industries. Its ability to resist corrosion ensures longevity and safety, making it a preferred option where performance and reliability are critical.

Corrosion Resistance: Zinc coating acts as a barrier against moisture, chemicals, and other corrosive elements, thereby significantly extending the rope’s lifespan, especially in marine and industrial settings where exposure to harsh conditions is common.

Strength and Flexibility: The core of galvanized wire rope typically consists of multiple strands of high-strength steel wires twisted or braided together. This construction not only provides exceptional tensile strength but also allows the rope to maintain flexibility, crucial for applications requiring bending around pulleys or sheaves.

Cost Efficiency: By sourcing top-quality materials at competitive prices, we ensure maximum value for your investment.

Global Shipping Solutions: Streamline your logistics with our comprehensive shipping options, including FOB, CFR, CIF, and convenient door-to-door delivery services.

Assured Quality: Transparency is our priority. Upon request, we furnish raw material test certificates and final dimensional statements for your complete assurance.

Swift Responsiveness: Our dedicated team commits to responding promptly, typically within 24 hours and often within the same hour of your inquiry.

Efficient Inventory and Mill Deliveries: We provide prompt access to stocked items and efficient mill deliveries, minimizing lead times.

Customer-Focused Approach: We prioritize trust by offering straightforward solutions and realistic timelines to meet your needs.

Bright vs. Galvanized: Bright wire ropes lack the zinc coating and are typically used where corrosion resistance is less critical, while galvanized ropes are preferred for outdoor and marine applications.

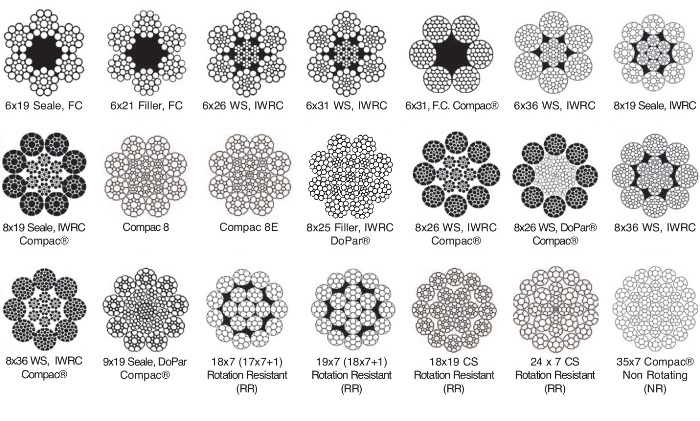

7×19, 6×19, 6×37: These refer to the construction of the wire rope (number of strands and wires per strand), each offering different strengths and flexibility characteristics suitable for specific uses.

We understand the importance of secure packaging, especially for international shipments. Our team uses various packaging methods tailored to the specific product and its journey.

Strength: Galvanized wire rope is made from high-tensile steel wires, offering exceptional strength and resilience against bending, abrasion, and fatigue.

Corrosion Resistance: Zinc coating protects against rust and corrosion, ensuring longevity in outdoor and marine environments.

Versatile Applications: Used in marine operations, construction, agriculture, transportation, and recreational activities like zip lines and suspension bridges.

Reliability: Trusted for securing heavy loads, providing structural support, and withstanding harsh conditions across various industries.

Durable: Engineered to maintain performance under pressure, making it essential for demanding applications worldwide.

Marine Industry: Used for mooring lines, towing, and anchoring due to their ability to withstand saltwater corrosion.

Construction and Rigging: Essential for crane operations, structural support, and lifting heavy materials on construction sites.

Agriculture: Used in farm machinery and fencing applications due to durability and resistance to outdoor elements.

Transportation: Securing cargo on trucks, trailers, and ships.

Recreation: Supporting zip lines, suspension bridges, and other recreational structures.

A: We offer 302, 304, 316 stainless steel in diameters from 0.15mm to 50mm.

We have various cable constructions and finishes (bright, dull). Black/white PVC coating available.

A: Contact our team to discuss your requirements.

Pricing & Shipping:

A: We source high-quality materials competitively.

A: FOB, CFR, CIF, door-to-door. We’ll advise on the most economical option.

A: We offer stock and efficient mill deliveries with minimized lead times. We’ll provide an estimated timeframe upon confirming your order.

A: We use rigorous testing methods (destructive & non-destructive) for complete assurance.

A: Yes! We provide raw material test certificates and final dimensional statements upon request.

A: Our team guarantees a response within 24 hours, often within the same hour.

A: Contact us directly. We may have it in stock or can help find a suitable alternative.

A: We are committed to customer satisfaction. We’ll provide honest solutions if we can’t meet your exact requirements.

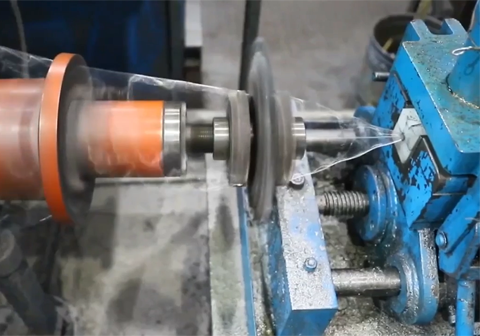

The process begins with wire drawing, where large steel rods are pulled through a series of dies to reduce their diameter. This process is repeated multiple times to achieve the desired thickness. The resulting wires are strong and have uniform diameters, essential for the integrity of the final product.

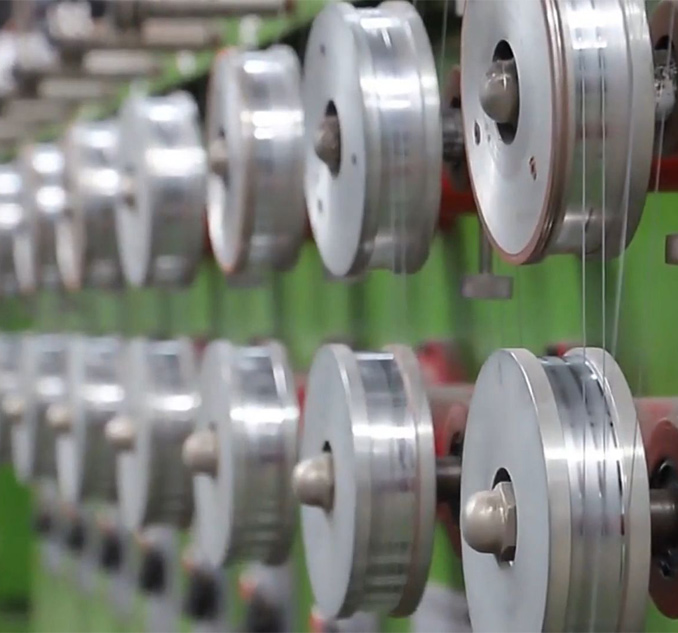

In this step, individual wires are twisted together to form strands. The image shows multiple wires being fed into a stranding machine. Depending on the required construction, these strands can be made from various wire configurations (e.g., 1×7, 1×19, 6×7). The stranding machine ensures that the wires are twisted with precise tension and alignment

For some wire ropes, strands undergo a compaction process to increase density and reduce the diameter. This compaction enhances the rope’s strength and fatigue resistance, making it suitable for more demanding applications.

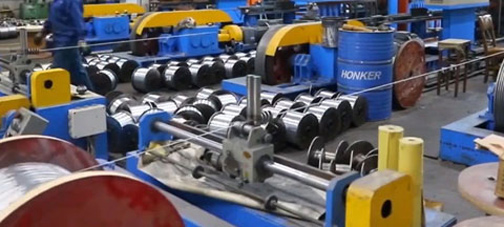

The next step involves twisting the strands together to form the final wire rope. This is known as closing or laying. The image illustrates multiple spools feeding strands into a closing machine, where they are helically twisted to form a rope. Different constructions such as 6×19 or 7×7 are achieved by varying the number and arrangement of strands.

For additional protection, some wire ropes are coated with materials like PVC. The coating process involves passing the wire rope through a coating machine that applies a uniform layer of protective material. Black and white PVC coatings are common, providing extra resistance to environmental factors.

Throughout the production process, rigorous quality control measures are implemented. This includes visual inspections, dimensional checks, and mechanical testing (such as tensile strength tests). The image likely represents part of this quality control process, ensuring each wire rope meets the specified standards.

Founded in 1989, our company has established itself as a leading expert in sourcing, designing, and producing custom wire rope solutions for a broad spectrum of industries. We work closely with a diverse range of clients, including buyers, engineers, architects, designers, and project managers, to deliver exceptional results that consistently exceed expectations.

Our team is deeply passionate about wire rope and dedicated to building enduring relationships with our customers. We aim to be a trusted and integral part of their supply chain, going the extra mile to ensure the highest quality by adhering to the strictest industry standards. Our in-house testing and material analysis equipment enable us to thoroughly test and certify all wire rope, fittings, and assemblies we produce.

We serve a wide array of sectors, including marine, outdoor adventure, fall arrest, fitness, machinery, construction, defense, engineering, vehicle recovery, fencing, agriculture, shade sails, theater, lighting, pest control, shop fitting, and interior design. In addition to wire rope, we also provide the necessary tooling and machinery to meet your specific needs.

Our headquarters and production facility are located in Taian City, Shandong Province, China. With a global network of trusted partners, we are confident in our ability to offer exceptional lead times and meticulously managed delivery schedules, no matter your location or project requirements. We are driven by a vision to accelerate our growth beyond 2020, creating new and exciting opportunities for our dedicated and passionate team.

Stainless wire rope is a versatile and durable material widely used in various industries due to its strength, corrosion resistance, and flexibility.