Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

When it comes to selecting wire for various applications, strength is a crucial factor that influences performance, durability, and reliability. Two common types of wire used in different industries are stainless steel wire and galvanized wire. Each has its unique properties, but determining which is stronger depends on several factors.

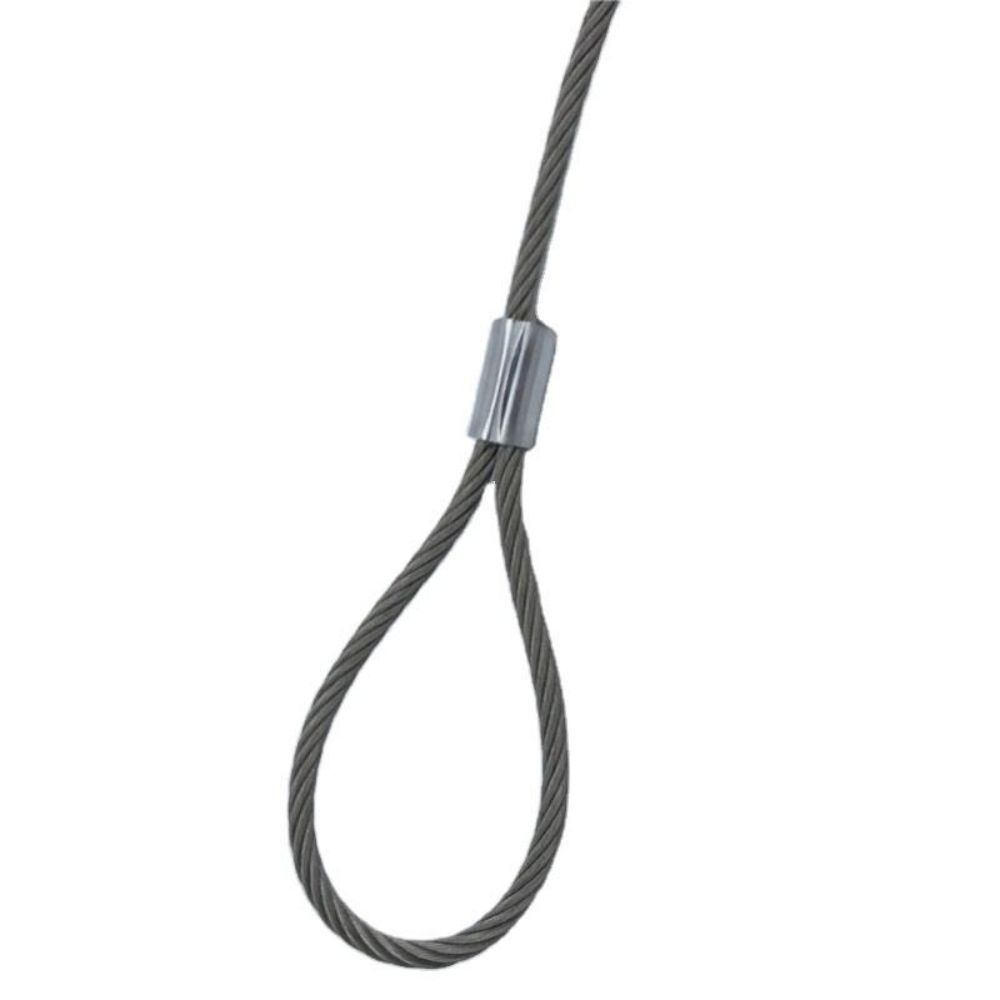

Stainless steel wire is renowned for its strength and durability. It is composed primarily of iron, with a varying percentage of chromium and sometimes other alloying elements like nickel or molybdenum. These alloying elements contribute to its corrosion resistance and mechanical strength.

High Tensile Strength: Stainless steel wire exhibits high tensile strength, making it suitable for applications requiring robust performance under tension or load.

Durability: Stainless steel wire maintains its strength and structural integrity over a wide range of temperatures and conditions, contributing to its long lifespan.

Corrosion Resistance: The chromium content in stainless steel forms a protective oxide layer that enhances its resistance to corrosion, even in harsh environments.

Galvanized wire is carbon steel wire coated with a layer of zinc to enhance its corrosion resistance. This coating process, known as galvanization, creates a barrier that protects the underlying steel from rust and corrosion.

In terms of raw tensile strength, stainless steel wire generally outperforms galvanized wire. Stainless steel grades like 304 and 316, for example, have high tensile strengths that exceed those of most galvanized steels. This makes stainless steel wire particularly suitable for applications where strength and durability are critical, such as in construction, marine environments, and industrial settings.

However, it’s important to note that galvanized wire can be adequate for many applications where moderate strength and corrosion resistance are sufficient, and where cost-effectiveness is paramount.

While both stainless steel wire and galvanized wire offer corrosion resistance and durability, stainless steel wire typically provides superior strength due to its alloy composition and manufacturing process. Choosing between the two depends largely on the specific requirements of the application, including strength demands, environmental conditions, budget considerations, and desired longevity.

By understanding the strengths and capabilities of each type of wire, industries and consumers can make informed decisions to ensure optimal performance and longevity in their projects.

A: We offer 302, 304, 316 stainless steel in diameters from 0.15mm to 50mm.

We have various cable constructions and finishes (bright, dull). Black/white PVC coating available.

A: Contact our team to discuss your requirements.

Pricing & Shipping:

A: We source high-quality materials competitively.

A: FOB, CFR, CIF, door-to-door. We’ll advise on the most economical option.

A: We offer stock and efficient mill deliveries with minimized lead times. We’ll provide an estimated timeframe upon confirming your order.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: