Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

When it comes to selecting the appropriate wire rope for a specific application, one of the most important factors to consider is the strength of the rope. Two of the most commonly used wire rope types are the 7×7 and 7×19 wire ropes. In this article, we will explore the differences between these two types of wire ropes and determine which one is stronger.

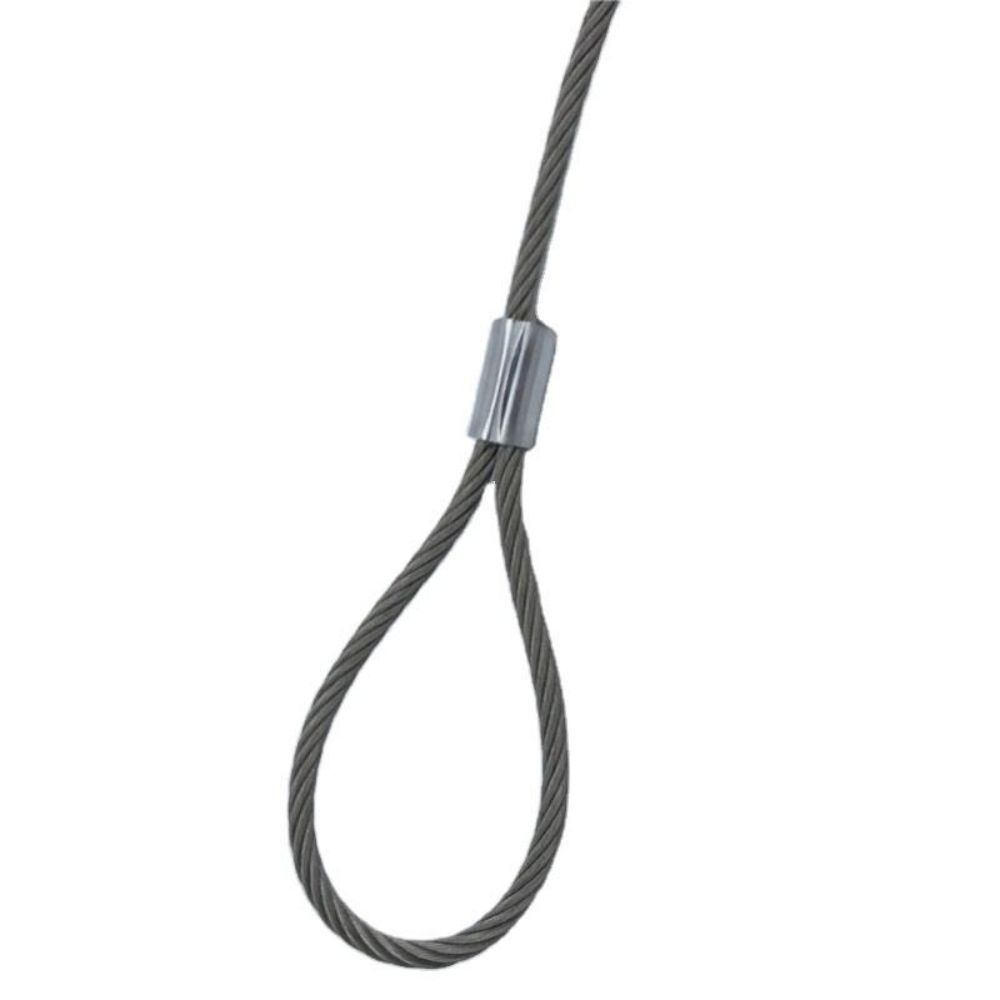

Before installing wire ropes, you need to take two critical steps. First, ensure the cable is stored correctly. Avoid keeping the rope in warm, confined spaces prone to condensation, as this can lead to wire corrosion. Instead, cover the cables with waterproof cloths to protect them. Additionally, store the wire rope on a reel to prevent direct contact with the floor, which can cause damage.

The second crucial step before installation is to verify the wire rope diameter. Use a parallel-jawed caliper to measure the rope and ensure it meets the manufacturer’s equipment standards. Incorrect sizing can lead to significant damage to the rope when it’s wound onto the drum and can also cause harm to the sheaves.

By following these pre-installation guidelines, you can help ensure the integrity and longevity of your wire ropes. Proper storage and accurate diameter measurement are vital steps to prevent damage and ensure reliable performance. Taking these precautions reduces the likelihood of failures and extends the operational lifespan of your wire ropes.

Additionally, the way in which the wire rope is used can also affect its strength. For instance, if a wire rope is subjected to frequent bending or twisting, it may become weaker over time, even if it is initially stronger than another wire rope. Therefore, it is essential to consider the specific application and environment in which the wire rope will be used when determining which type is best suited for the task.

In conclusion, while the 7×19 wire rope is generally stronger than the 7×7 wire rope due to the higher number of wires in each strand, it is important to consider other factors such as material quality and the specific application when making a decision. Ultimately, the best choice of wire rope will depend on the unique requirements of the project at hand.

A: We offer 302, 304, 316 stainless steel in diameters from 0.15mm to 50mm.

We have various cable constructions and finishes (bright, dull). Black/white PVC coating available.

A: Contact our team to discuss your requirements.

Pricing & Shipping:

A: We source high-quality materials competitively.

A: FOB, CFR, CIF, door-to-door. We’ll advise on the most economical option.

A: We offer stock and efficient mill deliveries with minimized lead times. We’ll provide an estimated timeframe upon confirming your order.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: