Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

First and foremost, it is crucial to understand the different types of stainless steel slings available in the market. The most common types include wire rope slings, chain slings, and synthetic web slings. Each type has its own set of advantages and disadvantages, and the choice ultimately depends on the specific requirements of the application.

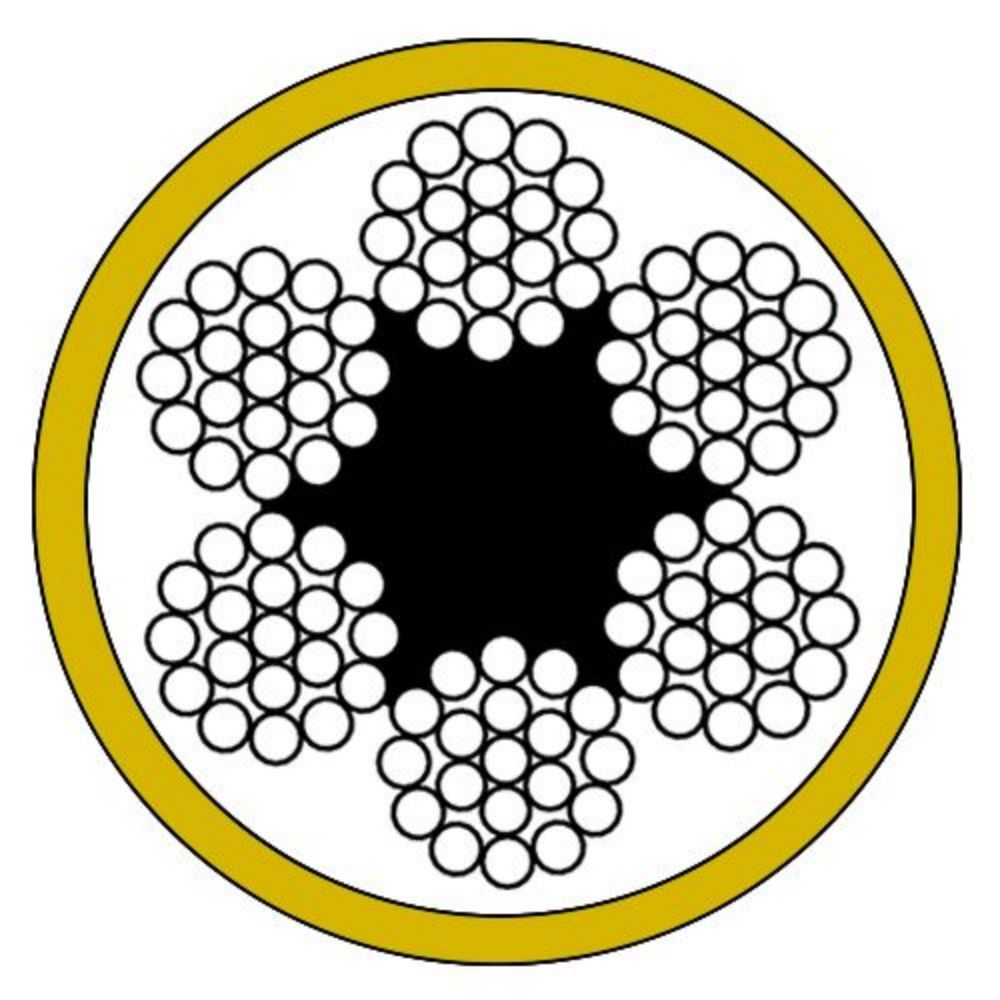

Wire rope slings are made from high-strength steel wire, which provides excellent durability and resistance to abrasion. They are ideal for lifting heavy loads and can withstand harsh environments. However, they can be more expensive than other types of slings and may require additional fittings for proper attachment.

Chain slings, on the other hand, are made from high-strength steel chains and offer a high level of strength and flexibility. They are suitable for lifting loads with sharp edges or irregular shapes, as they can conform to the shape of the load. However, they can be heavier than other types of slings and may require additional fittings for proper attachment.

Synthetic web slings are made from high-strength synthetic materials, such as nylon or polyester, and offer a lightweight and flexible option for lifting loads. They are easy to handle and can be easily adjusted to fit a variety of load shapes. However, they may not be as durable as metal slings and can be more susceptible to damage from abrasion or chemicals.

Once the type of stainless steel sling has been determined, it is essential to consider the specifications of the sling, such as the material grade, working load limit, and length.

The material grade is an important factor to consider, as it determines the strength and durability of the sling. Stainless steel slings are typically made from grades 304 or 316, with grade 316 offering better corrosion resistance in harsh environments.

The working load limit (WLL) is the maximum weight that the sling can safely support. This value should be chosen based on the weight of the load being lifted, as well as any additional factors, such as the distance the load will be lifted or the type of lifting equipment being used. It is important to ensure that the WLL is sufficient to handle the load safely and efficiently.

The length of the sling is another important factor to consider, as it determines the reach and flexibility of the sling. A longer sling will provide greater reach but may be more difficult to handle and store. Conversely, a shorter sling will be easier to handle and store, but may not provide enough reach for certain applications.

In conclusion, choosing the right stainless steel sling involves considering several factors, such as the type of sling, material grade, working load limit, and length. By carefully evaluating these factors and consulting with a knowledgeable professional, you can ensure that you select the best stainless steel sling for your specific application, ensuring safety and efficiency in your lifting operations.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: