Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Its utility extends to commercial, industrial, and military sectors, where it is used for cleaning, spring-loaded devices, reinforcement, structural integrity, and even musical instruments. However, not all steel wire is suitable for every purpose. It is manufactured with varying degrees of strength, elasticity, and thickness for different applications. Here’s a brief overview of eight common types of steel wire:

Named for its use in piano strings, music wire is the “workhorse” of steel wires. Its high carbon content provides excellent strength and durability, making it perfect for high-stress and repetitive load applications, such as springs and surgical tools.

Oil tempered wire, similar to music wire, is usually drawn to thicker diameters and then heated and quenched with oil to enhance its strength and flexibility. This type of wire is often used for springs, including those found in garage doors.

Broom wire is a strong, high-carbon wire that is typically galvanized or PVC coated to withstand repeated friction. It is most commonly used in the brushes of street cleaning machines.

This flexible, coated wire provides structure and flexibility, particularly in heating and air ducts that need to bend around corners while retaining their shape.

Hard-drawn wire is simply drawn to a specific diameter without additional treatment or tempering. It is suitable for forming wire shapes or springs but cannot endure high stress like music wire. Common uses include metal baskets, shopping carts, safety pins, and certain automotive parts.

This steel alloy wire is cold-drawn and heat-treated to provide exceptional strength, capable of withstanding shock and high-impact loads. It is an excellent choice for recoil springs in firearms and high-performance vehicles.

While high carbon content makes steel strong, it reduces flexibility. Low carbon steel wire bends more easily, making it suitable for low-stress springs and items like coat hangers. safety pins, and certain automotive parts.

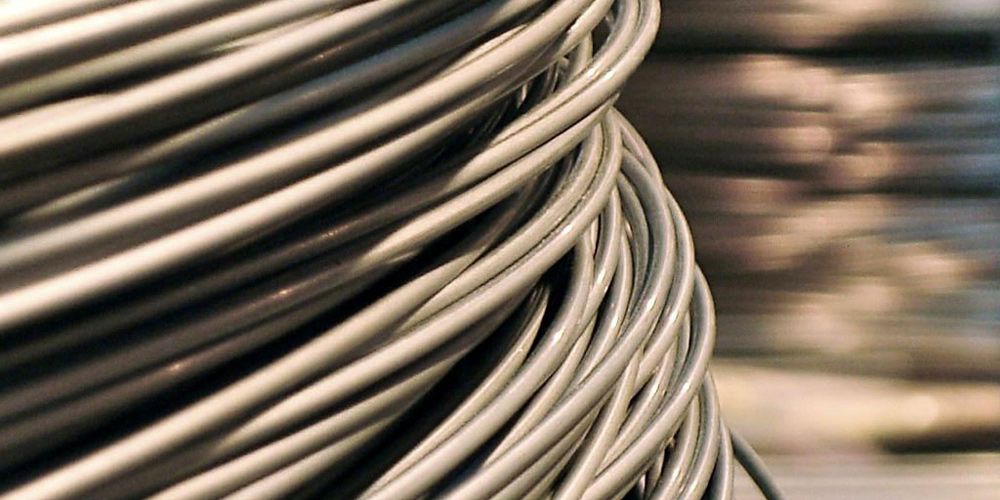

Patent wire undergoes a specific heating and quenching process to enhance its strength and durability. It is useful for high-tension applications and wire rope.

Understanding the various types of steel wire ensures that the right material is chosen for each specific application, maximizing performance and safety. By selecting the appropriate type of steel wire, users can ensure optimal functionality and longevity in a wide range of applications, from household items to industrial and military uses. safety pins, and certain automotive parts.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: