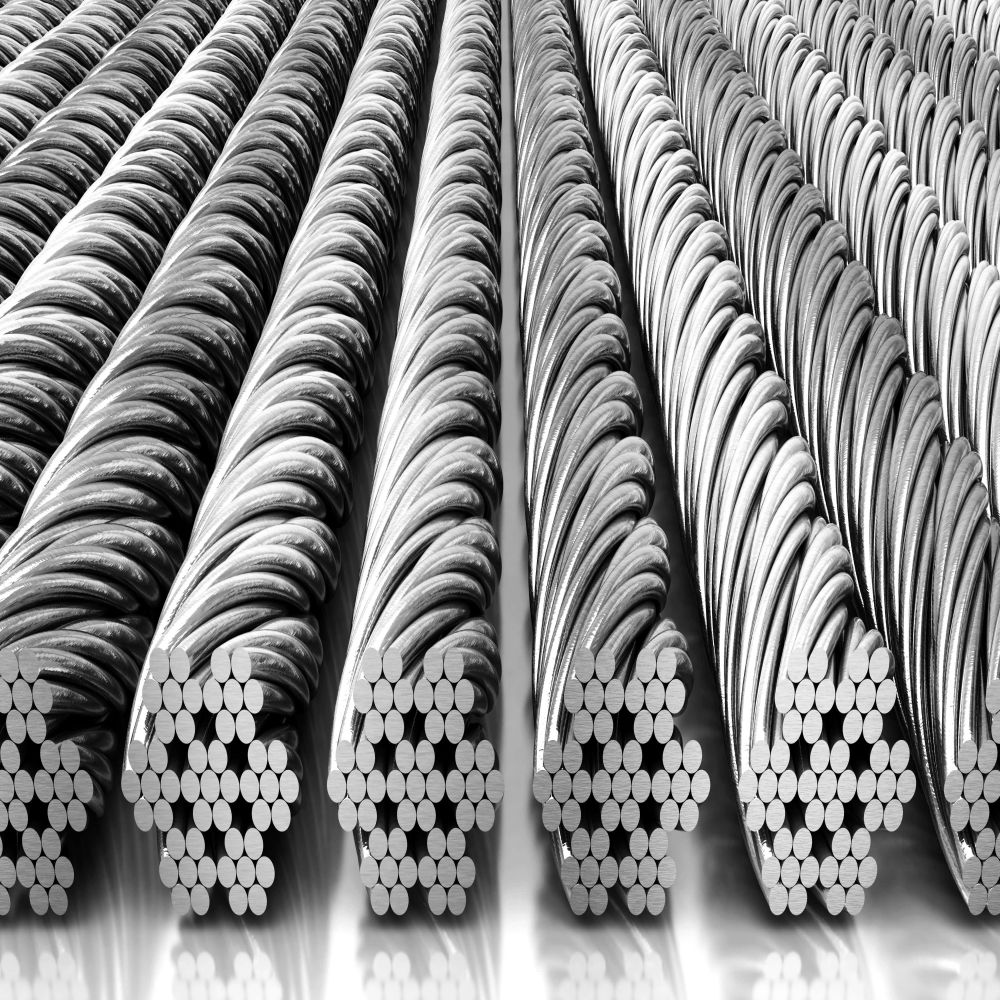

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

Its versatility allows it to be used in a wide range of applications, from construction and mining to marine and aerospace. In this article, we will explore some of the key application scenarios of stainless steel wire rope, highlighting its unique properties and the challenges it can overcome in harsh environments.

One of the primary applications of stainless steel wire rope is in the construction industry. It is often used in suspension bridges, cranes, and hoists, where its high tensile strength and corrosion resistance are crucial for ensuring safety and longevity. For example, the Golden Gate Bridge in San Francisco, which is exposed to saltwater and harsh weather conditions, relies on stainless steel wire rope to support its massive weight and maintain structural integrity.

In the mining industry, stainless steel wire rope is used in various equipment, such as conveyor systems, drilling rigs, and lifting devices. Its resistance to abrasion and corrosion makes it ideal for these applications, as it can withstand the harsh conditions and extreme temperatures often encountered in mining operations. Additionally, its high strength-to-weight ratio allows for efficient and reliable performance in heavy-duty applications.

The marine industry also benefits significantly from the use of stainless steel wire rope. It is commonly used in mooring lines, anchor chains, and towing systems, where its corrosion resistance and strength are vital for ensuring the safety of vessels and personnel. Stainless steel wire rope is also used in offshore oil and gas platforms, where it is exposed to corrosive seawater and harsh weather conditions. Its ability to withstand these challenging environments makes it a preferred choice for these applications.

In the aerospace industry, stainless steel wire rope is used in various components, such as landing gear, control cables, and suspension systems. Its lightweight nature, combined with its high strength and corrosion resistance, makes it an ideal material for these applications. Furthermore, its ability to withstand extreme temperatures and vibrations ensures reliable performance in the demanding environment of aerospace applications.

Another important application of stainless steel wire rope is in the renewable energy sector, particularly in wind turbines. The rotor blades of wind turbines are subjected to strong winds and fluctuating temperatures, which can cause corrosion and fatigue in traditional materials. Stainless steel wire rope, with its corrosion resistance and high strength, is an ideal solution for these applications, ensuring the longevity and reliability of wind turbines.

Stainless steel wire rope is a versatile and reliable material that can be used in a wide range of applications, from construction and mining to marine and aerospace. Its unique properties, such as high tensile strength, corrosion resistance, and lightweight nature, make it an ideal choice for harsh environments and demanding applications. As industries continue to evolve and face new challenges, the use of stainless steel wire rope will undoubtedly play a crucial role in ensuring safety, efficiency, and reliability in various sectors.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: