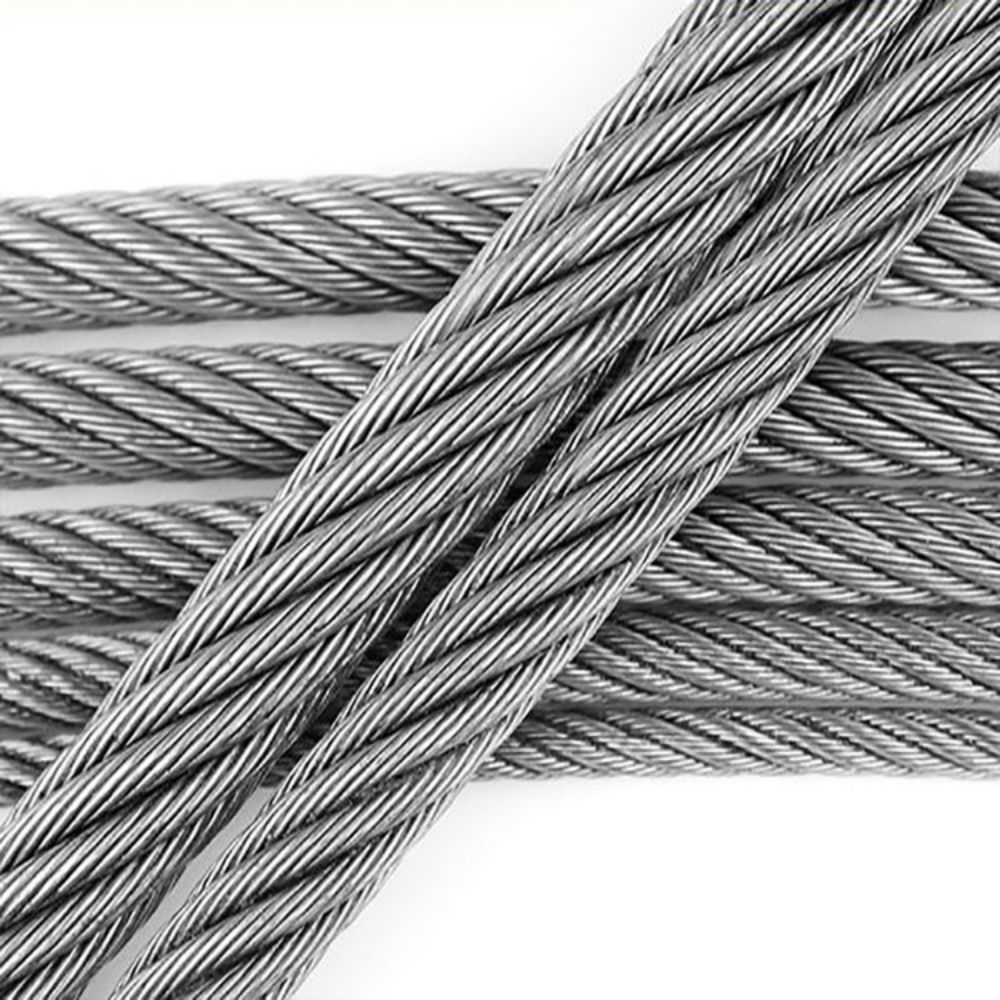

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

One of the most common types is the laid wire rope sling. It consists of steel wire strands laid in a spiral pattern around a core, which can be either fiber or wire. Known for its flexibility and ease of handling, the laid wire rope sling is suitable for a wide range of applications. It comes in various sizes and strengths to accommodate different load capacities.

Another type is the seamless wire rope sling, made from a single continuous strand of steel wire, eliminating the need for seams or joints. This results in a stronger and more durable sling compared to its laid wire counterpart. Seamless wire rope slings are ideal for applications requiring high strength and abrasion resistance, such as mining and construction.

For applications demanding even greater strength and durability, the fiber core wire rope sling is an excellent choice. This sling is made from steel wire strands braided around a fiber core, providing additional strength and flexibility. The fiber core helps absorb shock loads, making the sling suitable for heavy lifting applications. Fiber core wire rope slings are commonly used in the oil and gas industry for lifting and moving large, heavy equipment.

Galvanized wire rope slings are made from steel wire strands coated with a layer of zinc for corrosion protection. These slings are ideal for harsh environments where corrosion resistance is crucial, such as marine and offshore industries. They are available in various sizes and strengths to accommodate different load capacities.

Lastly, stainless steel wire rope slings are made from stainless steel wire strands. Known for their corrosion resistance and high strength, these slings are suitable for corrosive environments and applications requiring high strength. Stainless steel wire rope slings are commonly used in the food and beverage industry for lifting and moving food-grade materials.

Steel wire rope slings are an indispensable part of the lifting and rigging industry, providing a reliable means of lifting and moving heavy loads. With various types and configurations designed to meet specific requirements, understanding the unique characteristics of each type is essential for selecting the right sling for your needs. Whether you require flexibility, high strength, abrasion resistance, or corrosion resistance, there is a steel wire rope sling that can meet your demands.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: