Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

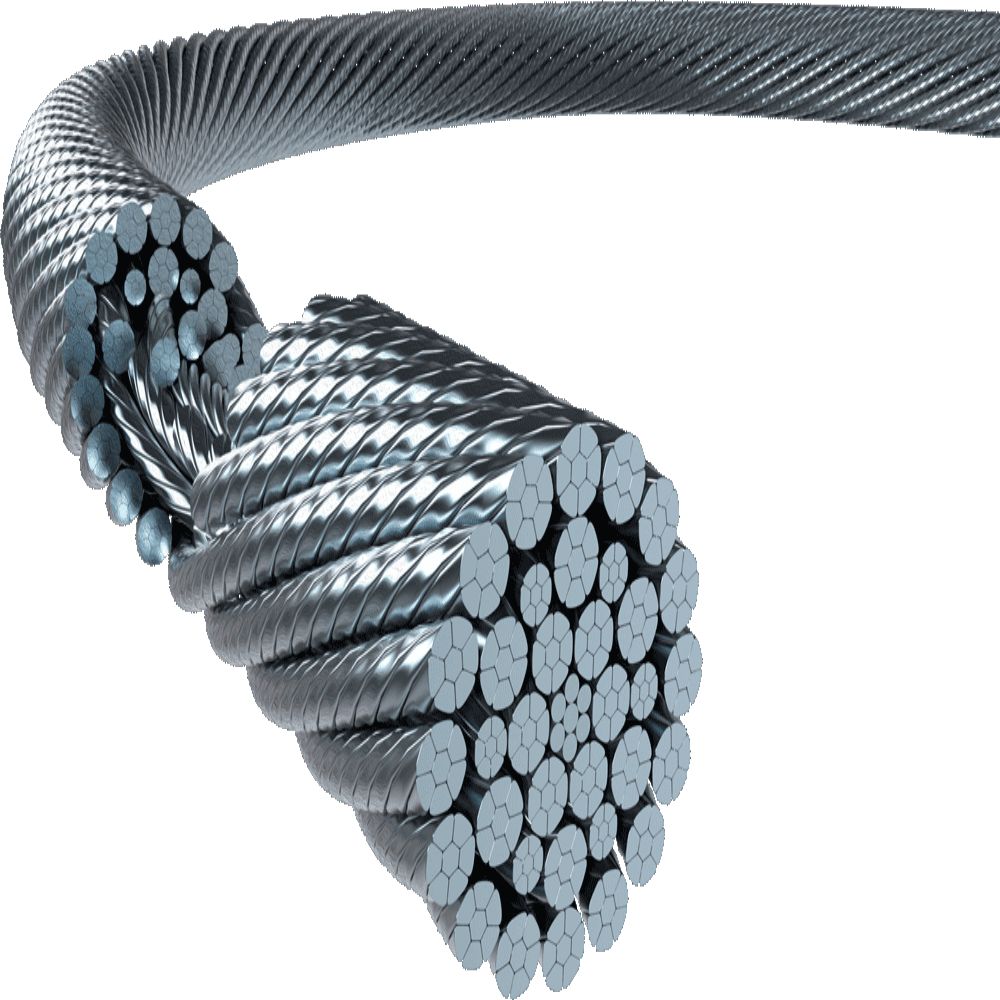

Steel wire rope is widely used in industrial and commercial sectors due to its varying properties in strength, flexibility, and corrosion resistance. There are two primary types of steel wire ropes:

Stainless steel wire ropes find use in civil engineering, aerospace, refrigeration, maritime industries, and more. They are particularly effective for securing cargo and adding decorative elements to architectural designs. In the marine industry, their corrosion resistance and strength make them ideal for mooring lines, anchor lines, and fishing lines.

The corrosion resistance of stainless steel wire rope largely depends on its chemical makeup. Higher chromium content enhances corrosion resistance, and adding nickel increases the wire’s strength.

Stainless steel wire ropes are preferred in moist environments due to their high corrosion resistance and versatility. Choosing the right material for each specific application is essential. Here are a few tips to select the best wire rope:

Stainless steel wire ropes commonly come in grades 304 and 316, both known for their corrosion resistance and frequent use in the marine industry. Key differences include:

Understanding the proper use and selection of stainless steel wire ropes is crucial due to their vital role in various industries. These ropes offer remarkable strength, durability, and corrosion resistance, making them indispensable in applications ranging from construction and marine to architectural and industrial uses. As technology advances, the demand for high-performance and durable wire ropes continues to grow, making it essential to stay informed about the best practices for their use and maintenance.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: