Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs:

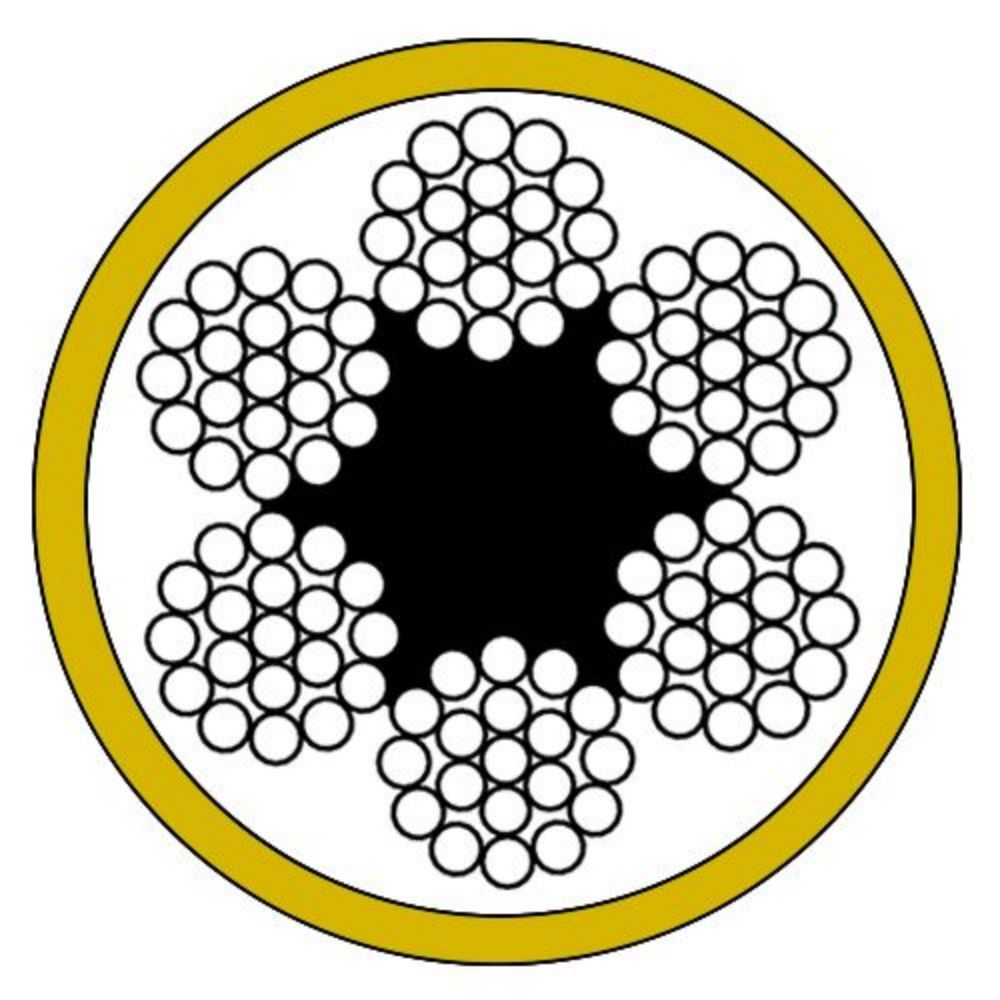

Simply put, wire rope is made of many steel wires wound around each other. This mass of wound wires forms a helical shape, creating the strength of the rope. This helical structure not only provides exceptional strength but also offers flexibility, allowing the rope to bend and move under different rigging setups without compromising its integrity.

Wire rope assembly involves taking the length of a cable and attaching fittings mechanically. This allows for secure connections to proper components. Crane wire ropes are specifically designed to lift heavy objects and transport them safely. These rigging supplies are integral to many operations and are used worldwide.

Wire ropes are designed to withstand various stresses and environmental conditions. Key features include:

Strength: The helical structure of wound steel wires provides exceptional strength, making wire ropes capable of handling heavy loads. This strength is crucial in applications where safety and reliability are critical, such as in construction and mining.

Flexibility: Despite their strength, wire ropes maintain flexibility, allowing them to bend and move through different rigging setups. This flexibility is essential for applications where the rope needs to navigate pulleys and sheaves without losing its structural integrity.

Durability: Wire ropes are made from high-quality steel and are often coated to resist corrosion and wear, extending their lifespan. The coatings can include zinc (galvanization), polymer, or lubrication, each providing different levels of protection based on the application requirements.

Wire ropes come in various types, each designed for specific applications and conditions. The main types include:

Galvanized Wire Ropes: Coated with zinc to protect against corrosion, these ropes are ideal for outdoor and marine applications where exposure to the elements is a concern.

Stainless Steel Wire Ropes: Made from stainless steel, these ropes offer excellent corrosion resistance and are suitable for use in harsh environments, including marine and chemical industries.

Fiber Core Wire Ropes: These ropes have a core made of natural or synthetic fibers, providing greater flexibility and shock absorption. They are used in applications where the rope needs to bend frequently and absorb dynamic loads.

Steel Core Wire Ropes: With a core made of steel wires, these ropes offer higher strength and resistance to crushing. They are used in applications where the rope is subjected to high tension and load, such as in cranes and elevators.

Wire ropes are essential components in numerous industries, providing strength, flexibility, and durability for a variety of applications. Understanding their structure, assembly, and maintenance is crucial for ensuring safe and efficient operations. Whether in construction, transportation, marine, or mining, wire ropes play a vital role in supporting and enhancing industrial activities worldwide. By focusing on the specific degradation mechanisms—fatigue, fretting fatigue, wear, and corrosion—we can better predict and mitigate the effects of repeated bending, thereby enhancing the reliability and safety of wire rope systems. Regular maintenance, inspection, and the application of protective measures are vital in prolonging the operational life of wire ropes.

Stainless wire ropes are vital for their strength and corrosion resistance. Blogs offer insights for professionals and DIY enthusiasts on their uses and benefits. Here’s what you can typically expect to find in these blogs: